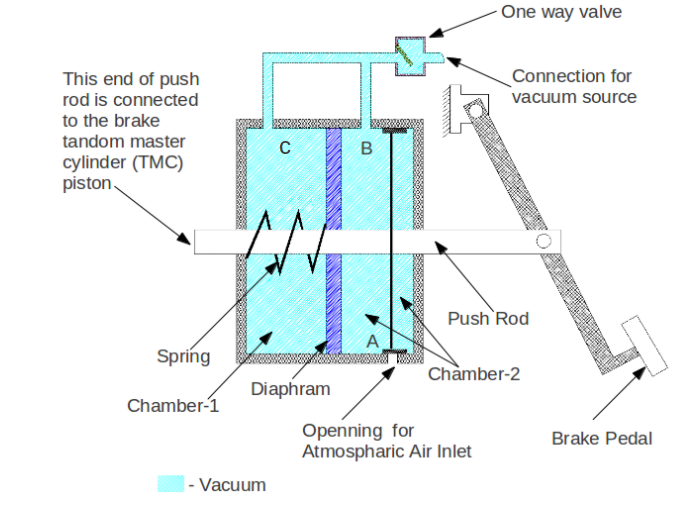

This video explains how a power brake system works. The pedal side of the diaphragm has two valves attached to the pedal arm.

This evacuates the rear chamber and assist in returning the booster to a state of rest.

How does a power brake booster work. A rod going through the center of the canister connects to the master cylinders piston on one side and to the pedal linkage on the other. Another key part of the power brakes is the check valve. The photo above shows the check valve which is a one-way valve that only allows air to be sucked out of the vacuum booster.

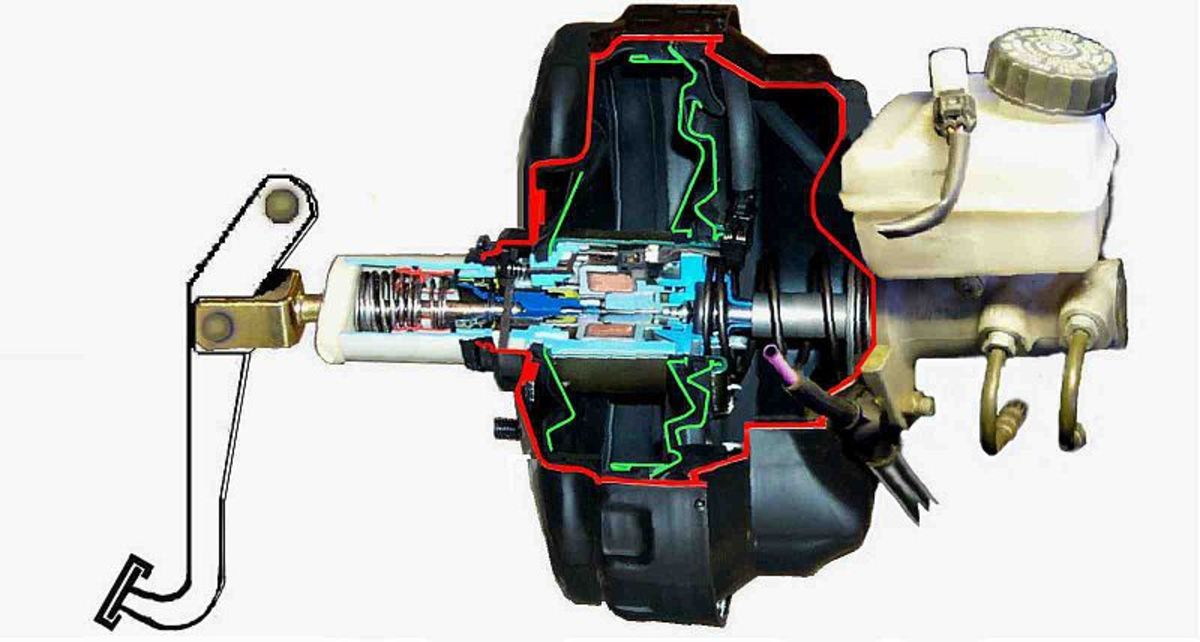

When the brake pedal receives pressure from the driver a shaft attached to the power brake booster moves forward thrusting a piston to the main brake cylinder. As a result brake liquid passes through the braking system. The brake booster on the contrary gives the pedal enhanced strength by using the engine vacuum counterbalancing the braking systems high pressure.

How do power brakes work. What is vacuum assist. How do brakes utilize a vacuum for added braking force.

This video explains how a power brake system works. Brake Booster is a brake safety component that is coupled at intermediate position between brake pedal and brake master cylinder and works as force multiplication component that uses engine vacuum to multiply the force applied by the driver on the brake pedal before further sending it to the master cylinder which in turn provide effective braking as well as drivers comfort in applying brakes. A power brake booster is installed and connected directly to the brake pedal.

When you press the pedal that movement allows the diaphragms to pull in air from the atmosphere which already has vacuum being pulled on them from the engine or some other vacuum source. Since most cars today have disc brakes at least on the front wheels they need power brakes. Without this device a lot of drivers would have very tired legs.

The brake booster uses vacuum from the engine to multiply the force that your foot applies to the master cylinder. Just like the name implies a Remote Mounted Brake Booster is a power brake booster that typically mounts in the trunk of the vehicle. The next logical question is How does it work There are two versions available.

Single and dual diaphragm units. The single diaphragm unit works well in a disc front and drum rear brake system. The purpose of a brake booster is to provide power assistance to the braking system meaning you do not have to put a lot of force on the brakes for them to actually engage.

The brake booster is located between the brake pedal and master cylinder and uses a vacuum to overcome the fluid pressure in the brake system. Hydro-boost brake boosters use the pressure of the power steering pump to power the brake booster. These systems can be mysterious to the untrained technician because part-swapping will not solve some brake issues.

The booster is essentially a power steering unit that supplements the drivers input. The power brake booster also helps to provide the force needed for the right amount of pressure to create an efficient application of force. It works by drawing power from a vacuum that is created by the engine during operation.

This is why power brakes only work while the engine is started. Hydro-boost power assist was introduced in 1973 by Bendix as an alternative to the vacuum booster. The hydro-boost uses the hydraulic pressure from the power steering system to provide the driver assist in applying the brakes.

There are three reasons why a vehicle may be equipped with hydro-boost instead of a vacuum booster. Hydroboost Brake Assist Hydroboost brake units use power steering pressure instead of engine vacuum for brake assist. This booster is sometimes necessary if the engine does not create enough vacuum to assist the braking system.

Diesel turbocharged and supercharged engines use these systems instead of vacuum brake assist units. When you steer fluid pressure is built up in the power steering pump due to the constant circulation of the power steering fluid. This hydraulic pressure in a hydraulic brake booster system is then stored in an area called an accumulator.

Releasing the brake pedal allow the internal spring to push the diaphragm and push rod back and operates the two-way valve. This valve blocks atmospheric pressure to the rear chamber. Simultaneously it opens the chamber to vacuum.

This evacuates the rear chamber and assist in returning the booster to a state of rest. The power assist system makes use of an ingenious booster that is powered by the vacuum generated in the engine intake manifold. For safetys sake the system must operate for at least one or two brake applications even if the engine stops and a small check valve is therefore incorporated to maintain the booster vacuum under these conditions.

The brake pedal is connected to the vacuum booster which is the first step of the force multiplication. The booster passes the force to the master cylinder which applies a compressive force to a liquid hydraulic or brake fluid and forces it through the brake lines to the brake calipers. Vacuum brake assist units use a large round flexible diaphragm enclosed in an assembly to create two distinct vacuum chambers.

The pedal side of the diaphragm has two valves attached to the pedal arm. These valves work together to control booster operation. A vacuum brake booster needs the right amount of vacuum to operate correctly.