Things are slightly different for a semi automatic gearbox that makes use of a set of actuators and a hydraulic motor in the places of a gear lever and clutch pedal respectively. The gear lever operated by the driver is connected to a series of selector rods in the top or side of the gearbox.

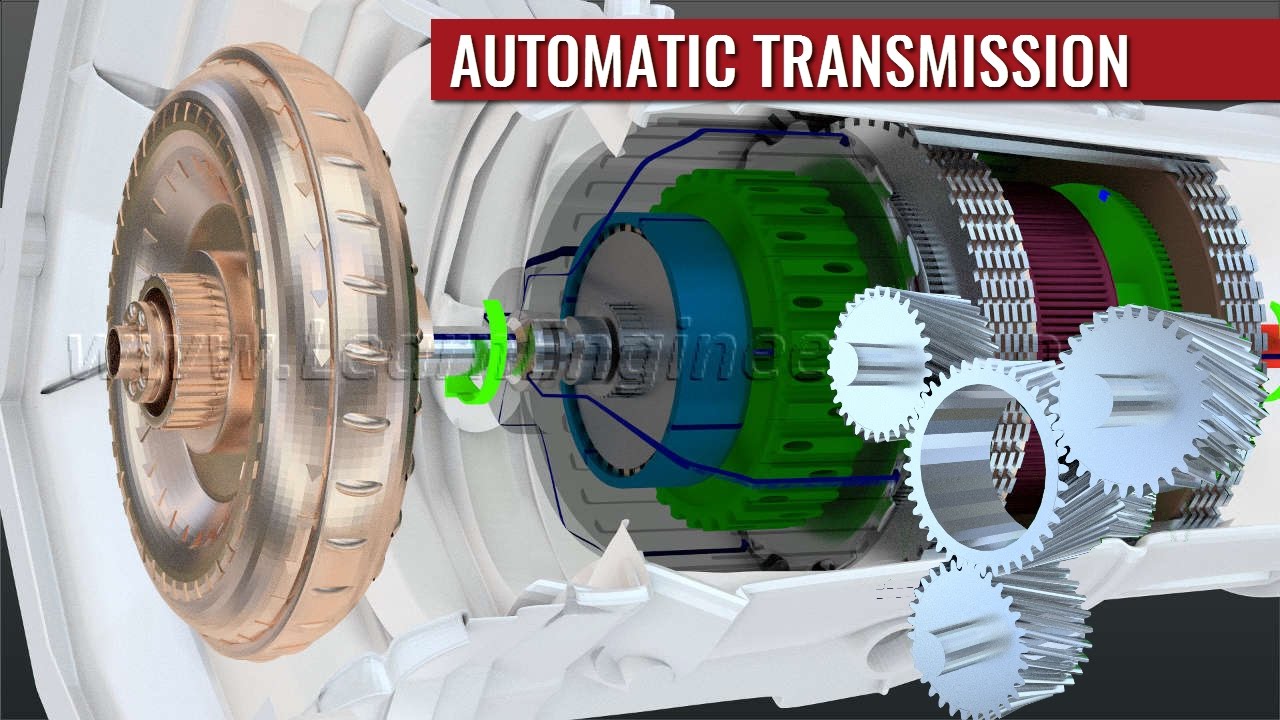

The most common type of automatic transmission is the hydraulic automatic which uses a planetary gearset hydraulic controls and a torque convertor.

How does automatic gearbox work. Most automatic gearboxes have three forward speeds and use two sets of epicyclic gears. The locking sequences of the epicyclic gear train are achieved by hydraulic pressure operating brake bands or multi-plate clutches. The bands are tightened round the ring gear to prevent it turning and the clutches are used to lock the sun gear and planets.

The gears of an automatic transmission include the following. According to How a Car Works when you shift your vehicle into drive you engage all available forward gear ratios. Third gear either locks the transmission in third gear or limits it to the first second and third gear ratios.

There are 2 ways your cars transmission will be controlled. It will either have a manual or an automatic gearbox. In the UK the majority of car gearboxes have been manual for years.

Its easy to understand why theyre called manual. You choose and select the gears yourself whereas with an automatic the car does it for you. A series of clutches also connect to the different parts of a planetary gear system.

Transmission clutches in automatic transmissions are made up of multiple metal and friction discs which is why theyre sometimes referred to as a multi disc clutch assembly. When the discs are pressed together it causes the clutch to engage. How Automatic Transmissions Work Purpose of an Automatic Transmission.

Location of the automatic transmission. Just like that of a manual transmission. Clutches and Bands in an Automatic Transmission.

In the last section we discussed how each of the gear ratios is. First and foremost your engines flex plate basically a flywheel for an automatic connects directly to a torque converter. So when the crankshaft rotates so does the torque converter housing.

The basic mechanical operation of a gearbox is explained on a drivetrain demonstrating the advantages of gearing axles clutch shifting and the application. An automatic transmission sometimes abbreviated to auto or AT is multi-speed transmission used in motor vehicles that does not require any driver input to change gears under normal driving conditions. The most common type of automatic transmission is the hydraulic automatic which uses a planetary gearset hydraulic controls and a torque convertor.

Other types of automatic transmissions. A sequential manual transmission is not to be confused with a tiptronic sort of automatic transmission. The tiptronic system may duplicate the shift lever motion of a sequential gearbox.

However because a tiptronic transmission is an automatic transmission at its core it still has the torque converter and usually does not shift as quickly. How does Automated Manual Transmission AMT work. In the current car market three widely used types of automatic gearboxes already exist namely the CVT Constantly Variable Transmission the DCT Dual Clutch Transmission and the Simple Automatic Transmission.

All of these use a gear and clutch arrangement much more complex and completely. Modern automatic gearboxes use a hydraulic fluid coupling called a torque convertor instead of a foot-operated friction clutch to change gears by locking and unlocking a set of planetary gears. It also stops the engine from stalling when a car is stationary and in gear.

An automatic transmission uses one of two kinds of kind of devices a manual valve or vacuum modulator to determine how hard the engine is working increasing pressure as necessary and prohibiting the use of certain gears depending on the gear ratio in use. Gear Box Working Principle. A Gear Box is an assembly consisting of various gears synchronizing sleeves and gear-shifting mechanism fitted inside a metal housing.

The metal housing usually made of aluminiumiron casting accommodates all the gears in it. Things are slightly different for a semi automatic gearbox that makes use of a set of actuators and a hydraulic motor in the places of a gear lever and clutch pedal respectively. There is also a control unit aka computer that is in the charge of various actions including engine torque the speed of the car accelerator pedal position and some others.

How Does a Semi Automatic Gearbox Work. Over the years the operation of semi automatic gearboxes have evolved as different manufacturers experimented with different systems to create the best performing semi automatic gearbox. Like any other transmission type semi automatics use the engines kinetic energy to turn the wheels of the car through.

Automatic transmission commonly associated with American car owners does all the work for the driver using clutches a torque converter and gears. Dual-clutch transmission DCT lies in between. The fork moves the synchromesh towards the selected gear.

Friction surfaces synchronise the shaft speeds and synchromesh and gear lock together. The gear lever operated by the driver is connected to a series of selector rods in the top or side of the gearbox. The selector rods lie parallel with shafts carrying the gears.