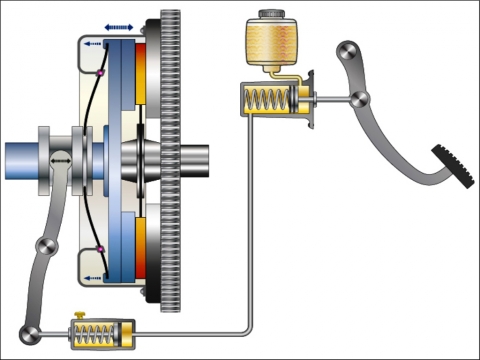

An additional option available when the truck is equipped with the hydraulic clutch system is an air assist system that reduces pedal effort when. Something similar happens in cars with a hydraulic system and a manual gearbox.

Something similar happens in cars with a hydraulic system and a manual gearbox.

How to adjust a hydraulic clutch. Your first step in adjusting a hydraulic clutch is to locate the slave-cylinder pushrod and determine if it is adjustable or not. The only way to adjust a hydraulic clutch is by adjusting the length of the slave-cylinder pushrod. If your pushrod is not adjustable you may be able to find a suitable replacement at a junkyard that you can install.

Something similar happens in cars with a hydraulic system and a manual gearbox. In this case the pedal needs to be pushed lower to actuate the clutch. The distance of the clutch can be a matter of personal taste.

You may prefer it more or less high. Set a block of wood down next to the clutch pedal. Mark the height of the clutch pedal without depressing it at all.

Press the clutch and measure its position. Press the clutch pedal several times. Mark the height of the clutch pedal at the location where you feel the clutch engage.

Hydraulic clutches are generally not adjustable in the same way that a cable clutch is. The only adjustment is in the height and free play of the pedal itself. This can be adjusted typically using a nut at the top of the clutch pedal lever.

In the hydraulic clutch system slacken the lock nut with two spanners then turn the adjusting screw. In cable operated clutch systems the brake and clutch pedals should be at the same height. A simple inspection will show if adjustment is needed - as is the case in the photo above.

Extrapolated over the 13 re-adjustments a manual-adjust clutch will typically require the maintenance savings alone can be significant. And thats assuming an operator is taking the vehicle in for a clutch adjustment whenever its needed - something thats trickier to do when a hydraulic linkage is paired with a manual-adjust clutch. Hydraulic clutch systems arent designed to be adjustable in the same way you would adjust a mechanical cable clutch.

While theres a popular belief that all hydraulic actuated clutch systems are non-adjustable or self-adjusting there are some designs that let you make adjustments to compensate for the typical wear and tear of your clutch discs friction material. Note the position of the wear indicating tab on the clutch. If the tab is near the REPLACE position the clutch should be replaced.

Locate four 4 38 x 16 x 1 14 UNC hex head machine screws. Install them in the 4 cover holes and turn them finger-tight. Support the Clutch during the removal of the 8 mounting bolts.

Well to start you need to remove the shifter from the transmission. Then remove the driveshaft. Then unplug the plugs from the side of the transmission and disconnect the clutch fluid line.

Then remove the crossmember. Being that it is a hydraulic clutch there is no adjustment. I know the system is sold as a unit and not as individual components so I have a feeling you got the wrong part.

Does it look like what I circled in pic 1. Wedge the clutch pedal in the fully raised position with a block of wood. Locate the clutch cable and find where the outer cable is seated against its cable stop on the edge of the bell housing.

The locknut and the adjuster nut are at the end of the outer cable next to the cable stop. With a hydraulic system it is all in the placement of the master cylinder push rod on the clutch pedal. The higher the pickup point is on the pedal closer to the fulcrum of the lever the easier it is to push the pedal.

There are three key factors to this equation. Pedal length pick up point to fulcrum length and master cylinder bore. There us no adjustment for your hydraulic clutch.

There may be an issue with your clutch master cylinder or with your clutches sticking. Being that it should still be under warranty we suggest telling your service department to come pick it up. Hydraulic clutch system to replace the traditional mechanical clutch linkage.

This system is standard on the 2010 ProStar and LoneStar and optional on the TranStar and WorkStar. An additional option available when the truck is equipped with the hydraulic clutch system is an air assist system that reduces pedal effort when. Hydraulic clutch systems have been used for years by motorcycle magnates KTM Husqvarna Husaberg and Beta.

They are also popular in factory racing circles such as HRC Honda. Thats because hydraulic clutches self-adjust offer better modulation than cable-actuated clutches and provide a more consistent feel.