Step 1 - Test the Voltage Output. Set up the scanner to read engine RPM and crank the engine.

Make sure to keep your meter lead wires away from engine moving parts during this test.

How to check crank sensor. Here is how you can easily test both your crankshaft position sensor and camshaft position sensor. Its very important to be able to test these sensor since. Connect your meter leads to the sensor pins.

Make sure to keep your meter lead wires away from engine moving parts during this test. Have an assistant crank the engine for a few seconds while you watch the meters readout. The sensor should produce a voltage pulsing signal.

If you dont see any voltage pulses replace the sensor. Set up the scanner to read engine RPM and crank the engine. The scan tool should read between 100 and 500 RPM.

A bad reading indicates that the crankshaft sensor isnt working right. A reading of zero indicates that the crankshaft sensor has failed completely. How to Test a Crankshaft Position Sensor.

Step 1 - Test the Voltage Output. To test if it your crankshaft position sensor is working properly you have to test the voltage output. Once that is.

Step 2 - Wiring the Voltmeter. Step 3 - Set the Multimeter. Step 4 - Set the Meter.

You have read the three possible ways of the crankshaft sensor test such as. Multimeter spinning resistance Test. Meter Test insulation and inductance resistance.

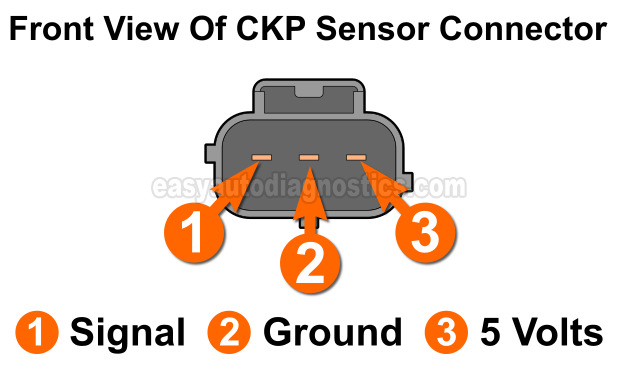

Testing A Three-Wire Sensor Now come to the three wire signal crankshaft position sensor test if this is what you have. Identify three of the wires. This time take the multi meter and set DC volts there.

Similarly turn the ignition key on without turning on the. You get the black probe that. Testing some pull down type sensors.

The crank sensor on your 46L or 54L Ford pick up SUV or car is a two wire type crank sensor that you can easily and accurately test with a multimeter in Volts AC mode. You dont need a scan tool to test the Ford 46L 54L crankshaft position sensor although a scan tool is a must have tool now-a-days. Another issue of a potential problem with the crankshaft position sensor is an illuminated Check Engine Light.

If the computer detects a problem with the crankshaft position sensors signal it will activate the Check Engine Light to alert the driver of the problem. A Check Engine Light can also be set off by a wide variety of other issues. The crankshaft position sensor test Im gonna show you here is one of the most effective and sure ways to troubleshoot the sensor using just a multimeter in Volts DC mode.

If you need to know if this 3X 18X crankshaft position sensor test applies to your specific 38L GM vehicle take a look at the Applies To box on the right and scroll with the leftright arrow buttons to see all of the applications. How to Check Your Crankshaft Sensor With an Ohmmeter. Park the vehicle and allow the engine and components to cool.

This can take 30 minutes to an hour depending on how long the vehicle was. The check engine indicator is on. As soon as the camshaft position sensor has certain faults then the light of this indicator will come on.

However here you should note that this indicator can also light up for other reasons. Thats why a professional should scan your vehicle and detect what the particular fault is. Things were fine for about another 5 or 6 months and then about 4 weeks ago the check engine light started coming on again and once again the code was for a the crankshaft position sensor specifically P0335 Crankshaft Position Sensor.

First check the condition of the sensor electrical connector and wires. Unplug the connector and check for rust or contamination like oil that is interfering with good electrical contact. Then check for wire damage.

Broken wires loose wires and signs of burns caused by nearby hot surfaces. Look for the CKP sensor at the front or side of the engine see Resources. It is usually held in place by a single bolt.

Lift the front of your vehicle using a floor jack and support it on two jack stands. Then unplug the sensor electrical connector and remove the bolt with a ratchet and socket. Making Sure The Crank Angle Sensor Is Getting Power.

To get our crank angle sensor diagnostic started were going to make sure that its getting 10 to 12 Volts DC. The wire that delivers 12 Volts to the crank angle sensor is the black with white stripe BLKWHT wire of the engine wiring harness connector. Check the crank sensor with an ohmmeter.

The first thing to check is to see if youre getting voltage to the sensor from the ECU. If it has more resistance than likely then it is the sensors fault. Always keep a Spare.