How to Test Serpentine Belt Tension Method 1of 3. Make sure the saw is turned off and unplugged before touching any part of the tool.

Measure belt span T.

How to measure belt tension. T st static tension N t belt span length m L belt pitch length m Y tensioning constant based on belt provided by manufacturer When the belt system uses a simple two-pulley configuration the distance between the pulley shafts is directly related to the tension on the belt so this distance can be used to determine the belt tension. How to Measure V Belt Tension Step 1. Make sure the unit is turned off and the pulleys you are working with are not moving.

Do a visual check of the V-belt to see if it is cracked or worn in any spots. Look for any shiny parts along the. Measure the distance from the center of one.

The Dayco Krikit gauge is available at your neighborhood Pep Boys in two sizes. The smaller is for v-belts up to 78 wide with a tension range of 30 to 150. Learn how to measure the tension of your Gates Carbon Drive belt with the Gates Krikit tension gauge and Gates smart phone appshttpwwwgatescarbondrivec.

Measuring belt tension with the Gates Sonic Tension Meter. Belt tension is measured by plucking the belt span while holding a sensor close by. To properly tension a synchronous belt place belt on pulleys and adjust takeup until the belt teeth mesh securely with the pulley grooves.

Measure belt span T. How to Test Serpentine Belt Tension Method 1of 3. Spotting the Signs of a Problem with the Tension.

Look for a warning light on your dashboard. Inspecting the Belt for Tension Issues. How To Know The Correct Tension.

Here I explain the procedure in order to have a properly tensioned belt wither it be a timing beltaltern. When the free span of a belt is plucked tapped or struck it will vibrate at a frequency known as its natural frequency. OTC 4748 Belt Tension Tool 1499Link to tool.

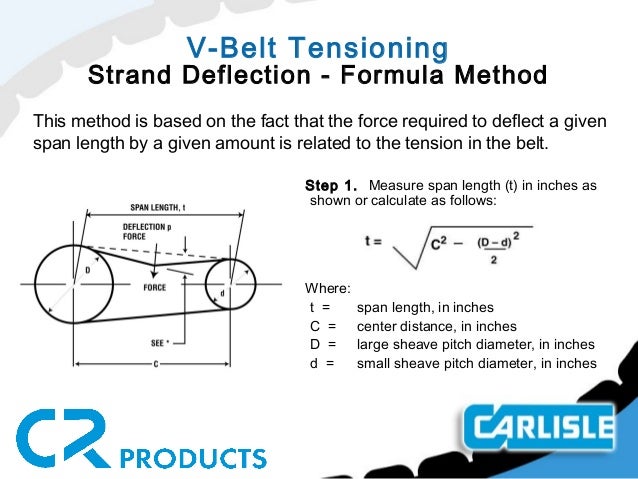

At center of the span length apply a force F using a belt tension gauge perpendicular to the belt span large enough to deflect the belt 164 for each 1 of belt span q. How to measure the tension on a drive belt. Slide the large O-ring to the recommended deflection distance onthe scale and slide the small O-ring up against the.

Place the large end of the tool onto the belt at the center. The first factor to calculate when figuring out conveyor belt tension is the tension needed to move the empty belt or TC. Tension Measurement Another tip for proper belt tensioning is a careful measurement of the belt on your conveyor bed.

Every belting supplier provides the recommended tension for each belt. This recommended tension is controlled by the distance between the edge of your belt and the end of the frame. Measuring Belt Tension by Frequency By measuring the natural frequency of the tensioned belt the tension of the belt can be calculated.

This method is applicable for V and banded belts. One way to measure the natural frequency of a belt is to use Carlisles Frequency-Finder. The rule tells you to place a finger in the middle of the belts between two pulleys and firmly press down.

Make sure the saw is turned off and unplugged before touching any part of the tool.