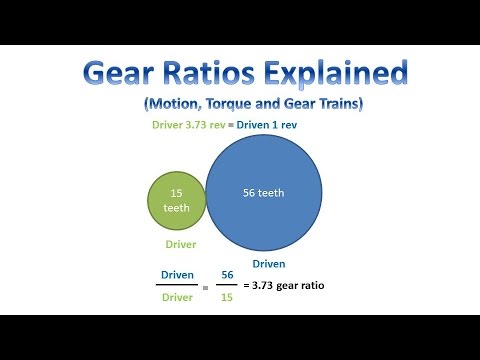

Usually the first gear is a drive gear attached to the motor shaft and the. They make it possible to determine exact gear ratios - you just count the number of teeth in the two gears and divide.

Usually the first gear is a drive gear attached to the motor shaft and the.

How to read gear ratios. Start with a two-gear train. Usually the first gear is a drive gear attached to the motor shaft and the. Count the number of teeth on the drive gear.

One simple way to find the gear ratio between two interlocking gears is. Count the number of teeth on the driven gear. The first gear set is 30 over 10 or 3 to 1.

And that the ratio across the second gear set is 40 over 10 or 4 to 1. This information can be used to determine the ratio across the entire series of gears. Thats done by multiplying the ratio of the first gear set by the ratio of the second gear set.

How Gear Ratios Work. To reverse the direction of rotation. To increase or decrease the speed of rotation.

To move rotational motion to a different axis. To keep the rotation of two axes synchronized. The gear ratio is the difference in the size of the pinion gear or input gear and the ring gear or output gear.

An example of this would be a gear ratio of 21. This would mean that the input gear would have two revolutions and the output would have one revolution. This results in a multiplication of torque or the turning force at the wheels.

They make it possible to determine exact gear ratios - you just count the number of teeth in the two gears and divide. So if one gear has 60 teeth and another has 20 the gear ratio when these two gears are connected together is 31. They make it so that slight imperfections in the actual diameter and circumference of two gears dont matter.

Gear ratios determine the speed at which a reel picks up line. Fishing reels with a gear ratio of 631 means the spool rotates 63 times for every 360-degree turn of the reel handle. Baitcast reels offer a wider range of gear ratios than spinning models for spinning rods.

In fishing reels the number that we see promoted as the gear ratio isnt a true gear ratio. Its a number based on how many times the spool rotates for each full turn of the reel handle. So if a reel has a 611 gear ratio it means that the spool turns 61 times for one full revolution of the reels handle.

Ratio The listed ratio represents the ratio of the input speed to output speed of the gear drive. A 11 ratio means motor and pump shaft speed are identical Figure 6. A 115 ratio for a motor running at 1770 rpm means pump drive speed will be.

1780 rpm 115 1190 rpm. If you find it makes three and a quarter rotations then your gear ratio is approximately 3251. Another gear ratio calculation formula is to count the number of teeth on the ring gear and divide them by the number of teeth on your pinion gear.

However you will have to take apart your trucks differential to access the ring and pinion gear. A basic gear ratio is one-to-one–or 101–which is the standard numerical specification for fishing reel gear ratios. With this ratio one turn of the handle produces one rotation of the spool.

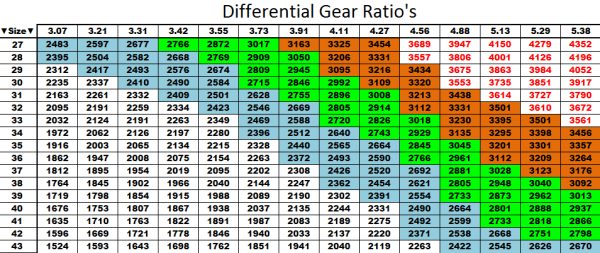

Rear end gear ratios or final drive ratio refers to the number of revolutions the drive shaft turns compared to one full revolution of rear wheels. A 290 gear ratio means the drive shaft turns 29 times in one full turn of the rear wheels. What are tall and short gear ratios.

Locate the Vehicle Certification Plate on the inside of the drivers door near the door latch. The axle code is printed under Axle or Ax You can use the chart provided in the first resource below to cross reference the axle code. You can verify the gear ratio using the next two steps.

Simply put the gear ratio rating of a fishing reel is measured by how many revolutions of the spool turns for every single turn of the handle. When we look at a standard gear ratio specification this is presented in three numbers. Computing for the gear ratio requires taking the number of teeth of the output gear and dividing this by the number of the input gear.

In our example that is 2010 or 2. The ratio therefore is 21 also known as gearing down. To find the axle gear ratio of any GM vehicle locate the RPO sticker typically located in the glove box and write down any codes starting with F G or H.

Then find those codes in the table below. The bottom line begins with the ratio being the first set of numbers. If an L is included it was equipped with a limited-slip differential or Traction- Lok.

The middle number is the ring gear diameter in inches typically an 8 or 9. The last set of numbers is the vehicle plant code. The ratio is the number of teeth on the driven gear ring divided by the number of teeth on the drive gear pinion.

So if the ring gear has 37 teeth and the pinion has 9 teeth the ratio is. Bicycle Gear Ratio Chart Calculator How to calculate bicycle gear ratio. Simple just divide your rear cog size from your front chainring size.

If you know their numbers just input them below and well calculate it automatically for you. Gear ratio set ie AM20 This code was added to identify ratios. Some early 1969 transmissions did not have this code.